Climate action with Low Carbon Timber

Transport distances as an indicator of climate-friendly low carbon wood products

Climate change is among the most crucial political, economic and social challenges of our time. We must put in all our efforts to reduce gas emissions, achieve ambitious goals and prevent economic damage whenever possible. Wood is a renewable resource and an important step on the way towards the above goals, but nevertheless it is important to assess the carbon balance of a finished wood product. The positive effects of carbon storage of such a product should not be outweighed by high emissions.

Climate-friendly manufacture of wood products is mainly about two main points:

- CO2 optimisation of timber industry techniques (lifecycle phase A3)

- CO2 reduction by means of cutting down on excessive non-productive transport (lifecycle phases A2 and A4).

For a number of reasons, shortening the transport should be the key and central action.

I. On the national, EU and global scale, transport has a large and growing negative effect on the environment:

- Globally, transport ranks third among the causes of climate change.

- Transport is the only sector in the EU which has despite all the efforts and measures such as bio-fuel, EURO-Norm and e-mobility not managed to decrease its CO2 emissions but has increased them instead. The main reason is the rebound effect stemming from the fact that every increased-efficiency procedure is even more carbon-intensive.

- Emissions in freight transport have been on the increase in the recent decades and are forecast to continue their climb in the future.

- The share of freight vehicles (in road transport) has gone up dramatically over the last decades and will remain high in the future.

II. Transport (if it does not decline) is the main component of the environmental performance evaluation:

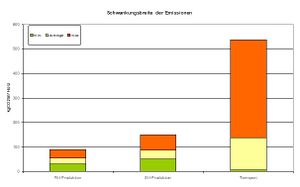

- Fluctuations or deviations of various timber industry companies with regard to production-technical emissions are mainly comparable and minor averaging at about 25% (according to a 2012 study by the Thünen Institute). This means that differences between various providers are minimal and the potential of reducing carbon footprint is small.

- The differences in transport distances travelled for the supply of raw materials and freight routes of the supply chain may amount to several hundred per cent, as shown in Fig. 1. This means that transport has a higher impact on the carbon balance of equal wood products tan production processes.

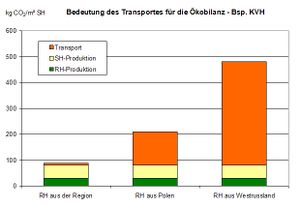

- Emissions resulting from transport take up a much higher percentage than any other type of emission, as shown in Fig. 2 based on a real case of round wood sourced for construction timber in Germany.

- The share of transport in the carbon balance keeps increasing as the environmental impact of production improves (not due to ecological motives but for cost optimisation).

III. Of all carbon balance components, transport can be changed most efficiently and most easily in a short term:

- Of all the factors affecting emissions, the flow of goods in the manufacturing chain can be changed and controlled with the quickest and most efficient effect. A change in demand can easily affect a batch of deliveries, directly changing delivery terms and conditions and reducing the carbon footprint. On the other hand, production techniques will not be changed on the basis of individual inquiries.

- Any change of manufacturing methods aimed at reducing CO2 emissions is generally linked to extremely high investments which a company is not motivated to make if the benefits are not high enough. Therefore, the said lever is not very promising and the effects it will yield a much lower effect than desired.

- In addition, the costs of assessing certain specific production emissions for a company can be very high. The company would need its own ecological performance evaluation which is extremely expensive and as such puts SMEs at a disadvantage. Besides, it is possible that the companies concerned would not accept and use the appropriate instrument, and the desired effect would not be achieved.

- Transport costs (affected by fuel prices and excise duties) are not the right mechanism in itself because they do not take up a high enough share in the entire cost structure. Other factors play a more important role in selecting the transport operator and origin of the goods.

In diesem Sinne sind Holzprodukte, die nachweislich regional mit überdurchschnittlich kurzen Wegen hergestellt worden sind, 'Low Carbon Timber' Produkte.

Inhalt: G. Bruckner und P. Strohmeier für HOLZ VON HIER.